Too many pictures to share so I'm going to post this in parts. Check out parts 2 and 3 at left.

Early in May we were invited to teach workshops in Chadron Nebraska. We had lots of help too, including:

Amy Sue from WI

Roy R from Long Island (electronbaby on fieldlines.com): http://windsine.org/

Marc S from Chadron NE: http://www.windfarmer.us/

Chris (the home owner): http://www.kingcanyonbuffalo.com/aboutUs.aspx

All sorts of wonderful ladies and an off grid 'commercial kitchen' and lots of really good food every day, and folks played music in the evenings. Incredible. Throughout 12 days, about 20 folks were involved with more projects than I can probably count. (they included bees, bison, beer, wind turbines, moving batteries, building a listeroid and an alternator for it, taking down a 'dead' ARE wind turbine, building and installing two homebrew 12 foot turbines and building one tower, baking bread, making lots of food.... that's a bit of it anyhow)

When we got there, Chris had about 2 kW of PV and an ARE 110 wind turbine. The ARE 110 is about 2 years old, it's been on and off broken down over half its life and completely broken down for the last 6 months. ARE has, in my understanding gone bankrupt and been 'replaced' by Xzeres wind energy. This machine has been acting 'shorted out' for 6 months. At this point we expected to see a burnt out stator, the machine wont turn quickly and it's been completely disconnected at the tower top for 6 months or so.

Marc was up there on the tower top (120 foot guyed lattice) for about 5 hours while it came down.

One piece at a time.

While the ARE turbine was coming down we were busy building 12 foot turbines from scratch. Pictured above Scotty facilitates some blade carving.

One of the goals while we were there was to build a tilt up tower for a 2nd installation. Pictured above are the anchors ... I don't think they'll be going anywhere. A LOT of concrete for this one!

While George and Scotty were working on metal and wood work (respectively) I was working on stators and magnet rotors.

These NRG MET towers were a bargain. They're 60 meter tilt up towers, made from galvanized 8 inch diameter 10 gauge tubing. Lots of this stuff is becoming available it seems (for cheap) - if you want an inexpensive tower you might look for these. Our goal here was to build a 134 foot tall tilt up tower out of this stuff.

There is already a system on this site, that uses 16 L-16 batteries and powers everything. (it only has a 4000 Watt Magnum 240V inverter). The system is more than sufficient for his house but not up to the job of running the commercial kitchen or the metal shop. So a new system is being installed. Here he's got 16 very large trojan IND17 6V batteries on the trailer waiting to be installed under ground in a 'vault'. These batteries are rated for 897 amp hours at a 20 hour rate.

George and Ken working in the metal shop. Throughout our stay I think they finished metal work for 4 12 foot machines.

This is the backup generator. a 1953 GM diesel 50kW machine. A bit loud, and a bit overkill.

Very nice stator molds. Two were made (we only used 1, hate to deface such nice stuff by using it!)

Rom, from Brazil fixin' to cast magnet rotors.

Pictured above Delbert is starting to cast a stator.

Julie, Rom, and Delbert working bubbles out of the resin.

The lid on the mold ready for some clamps.

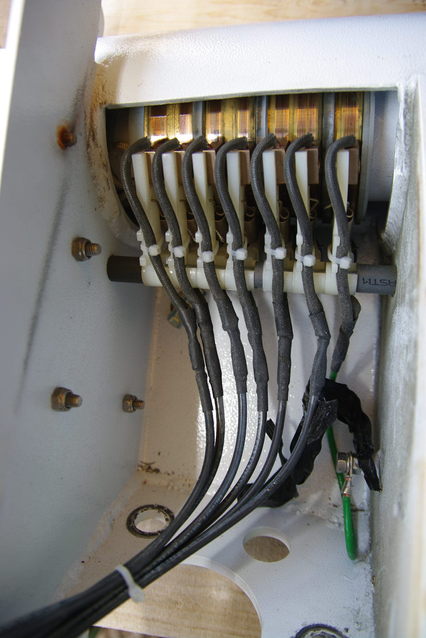

So we got the ARE turbine in the shop. Turned out the stator was fine... what we did find was a short between the slip rings and ground somehow. There were also cracks in some of the slip rings.

Roy and George kicking back behind the ARE alternator. I guess that should be about it for part one of this. It was quite a lot of fun and very busy.

See more -- parts 2 and 3 at left!