You are on Part 2 -- Parts 1 and 3 at left!

Pictured above Delbert is assembling the alternator for the first 12 foot wind turbine.

There is most of the group pictured next to the first machine we finished.

Marc and his son Stevie did all the tower climbing throughout the week.... and did most of the work to build the tilt up tower.

One 12 diameter homebrew machine at the base of the 120' lattice tower, ready to go up.

It was quite tricky for Stevie to get the turbine placed up there... took over an hour, we were running right up against dark.

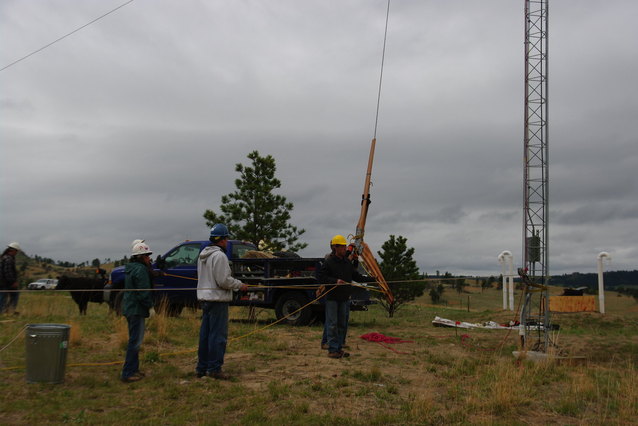

People on tag lines soon to have sore necks (not nearly as sore as Stevies back though).

So on the first pick we sent up the alternator with the tail attached. Second pick was the whole rotor assembled.

Up go the blades!

Fitting the blades was a lot easier than getting the turbine over the tower stub. It went smoothly.

Pictured above Roy is popping his head out of the ground where the batteries and the balance of system live.

While we were there, we also built this... from a 'kit' ~ which means.... this engine has metric, standard, and whitworth hardware on it. It came with no fuel lines, missing whitworth nuts and studs, no fuel lines, 6 mufflers, 4 air cleaners, no head gasket, no fuel tank.... etc (you get the idea). A lot of attention to detail with these machines, even more when they come as a 'kit'. At any rate, we cleaned the sand out of it and got it together and running.

Me demonstrating a tower model we made so folks would have some clue what we were actually trying to build.

And there the tower is, layed out on the ground.

There is the tower with the gin pole.

We used Marcs hydraulic winch to raise it.

10 days after we got there we got the 2nd machine raised on the tilt up tower at 134 feet. Both machines seemed to work fine.

Don't miss Part 3 at left. Crunch time!