So I have tons of pictures saved up over the summer and here is 'part one' of our adventures this summer. This posting will likely be the first of several I fire up here in short order. I do like to write about all our adventures - we've had lots, and I'm way behind on posting about stuff.

We went back to the Dan Chiraz's Evergreen Institute in July this summer. We did this last year and there is a page about that here: http://otherpower.com/evergreen2009.html

This year was similar. It was late July and incredibly hot (much hotter weather than last year). To do a workshop in MO, in a large steel building, with perhaps 90% humidity and having days when we hit 105 deg F, was challenging. It did go fine though and following are a few pics of the adventure.

Pictured above are pretty much all the 'raw' materials we started with. This is enough stuff for 1 each: 7', 10', and 12' diameter wind turbines. It is fun to teach a workshop where we can pile all this up, then discuss the physics/theory of wind and electricity, and at the end of the day have 3 nice looking machines.

Normally I bring lots of nice water jet parts for these workshops. This time - I had ordered the parts, but the table broke down so I brought very few with me. All the rotors and most of the other stuff had to be cut from flat steel with the oxy acetelene torch. Pictured above is one magnet rotor in progress. It really is more fun this way but very time consuming. I should also add, that at this workshop we had a very small drill press (fast running, small motor antique sort of thing) -so hole saws were out of the question on that. We also had an inexpensive Harbor Freight sort of welder with flux core wire. It's challenging, but fun... to work with the most simple, possibly 'marginal' tools - and have it all work out fine!

Pictured above the magnet rotors for the 12 foot diameter turbine (15 inch diameter cut from 3/8 inch steel) are about finished up.

This very neat looking spider was hanging out just outside the shop during the workshop. At the end of the week it was perhaps an inch and a half long.

After about 3 days, the 'metal work dept' run by George had produced all this nice stuff!

Pictured above was the other pet that was hanging out with us in the evenings, in the shop. Here where we live, we don't see many such critters.

Above is the first machine we finished, the little 12 Volt 7 foot diameter one.

The stator for the 12 foot turbine came out very nicely. It's a 48 Volt machine, we wound the coils with 70 turns ea, using two strands of AWG 16 wire. The magnet rotors each have 16 magnets 2 inch diameter x 1/2 inch thick.

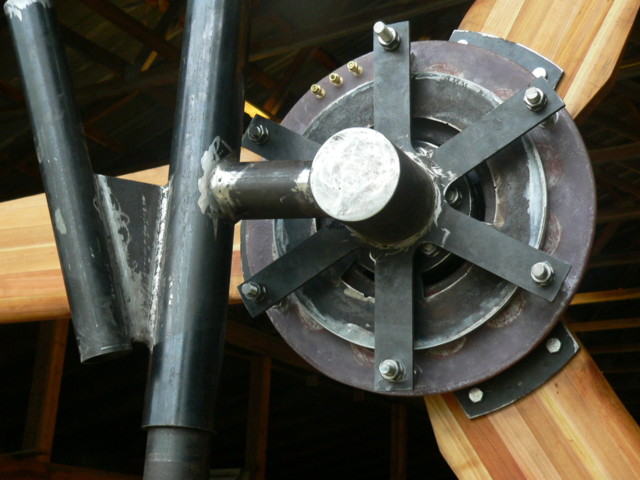

In addition to all the other tricky metal work, we made the students fabricate steel blades hubs for the 12 foot machine. It doesn't seem that tricky, but it takes some time and talent to produce nice parts like these when you're beating your head against flat steel with a cutting torch, and a small drill press, especially if you don't have much experience with such tools.

Pictured above is the back side of the 12 foot machine. It came out very nicely... missing from the photos is progress of the blade work. Scotty was with this workshop for 4 days to help with that and as usual the blades came out about perfectly.

There is the whole group. It was a very good, very hard working group -especially considering the temperature!

Above is a picture of the back of Scotty's car just before he went home. He picked up this nice old Mercedes 300 turbo for $800 at a garage sale. It had already been converted with dual tanks and all the other important stuff to run on recycled vegi oil. He drove out for free. During the workshop he built a portable filtration system so that he could pick up oil on the road, filter it - and keep going. His total fuel cost for the 2000 mile round trip was about $0. That was not the case for George and I. We made the 1000 mile drive to Gerald MO in my fairly beat up 1966 Volvo wagon. We averaged about 26mpg. After that workshop, we had another one to teach at Eastern Michigan University just outside of Detroit MI... in two days. So Scotty headed home, we headed North to MI. More on that in my next posting.