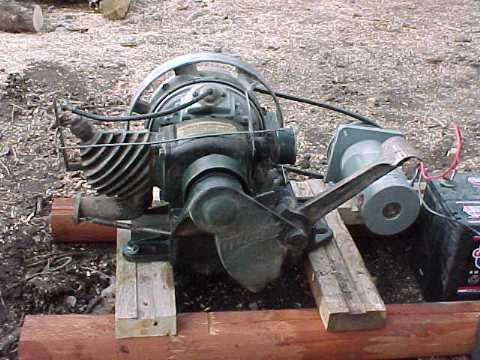

This page features a small battery charger we built from an old "antique" Maytag gas engine, and a computer tape drive motor. We only spent about an afternoon on this one, so lots of room for improvement probably exists.

These motors were popular back in the 1930's, and were built by Maytag, mostly for use in washing machines, although other accessories were available to be used with them, including a small battery charger, similar to this. I found this motor at a local "flea market", and they can be easily found. If interested, a good one can usually be had from Ebay for less than $200! These are 2 stroke motors, with an interesting governor. When the engine comes up to speed, a centrifugal governor breaks a contact in the ignition, preventing the engine from firing. When idling, the engine will hit about once per second, about once per every 6-8 strokes. When under load, the engine will fire however often is required to maintain speed. Neat looking, and sounding engines, they are also very reliable and easy to start. All these Maytag engines have kick starters.

The base is made from treated posts and 2X4's held together with lag bolts. The generator is one of those old computer tape drive motors which make excellent low rpm generators. We try to always offer these on our products page, but if none are available, they can usually be found on Ebay. Although not yet tried, good chance this whole charger would work better with an alternator or an old car generator for reasons which I will explain later. The generator has a 5" pulley on it, the gas engine has a 4" pulley, stock for the Maytag engine. This setup works reasonably well for charging 24 volts, but when hooked to 12 it bogs down the engine too much and it dies. To fix this, a higher rpm generator could be used, or a larger pulley would do, probably 6-8" diameter on the generator.

In conclusion, with a well tuned engine and the right pulley combination this unit should do a fine job of charging at about 150 watts. There are certain drawbacks to both this type of engine, and the generator we are using. The engine is a two stroke, they tend to be noisy and inefficient, but..they sure are cute, and fun to watch. Maytag engines are an excellent value where antique engines are concerned. They are still easy to get parts and support for. The tape drive motor we are using makes a fairly good generator, with the right sized pulley. The drawback, they don't cool very well, and if run for extended periods at full output (about 15 amps) they will get hot! An improvement might be to use an old car generator or an unregulated alternator and use an appropriate field resistor to properly match the load to the engine. Although not "ideal" a charger like this could easily be used to recharge small systems or car batteries. A more efficient design would probably be a modern 4 stroke engine (like a briggs from a lawnmower) and an alternator. That sort of setup could easily provide 500 watts or more, and might even use less fuel! Let us know if you have any comments or questions about this project! We are always experimenting with odd ways of making electricity and love to hear input on that matter!

What in the world could all those magnets be doing stuck to that big flywheel? This could be our next inefficient gas charger!